Euro Manufacturing and Marketing Ltd

UK Manufacturers of

Battery Management Systems,

DC-

TEST PROCEDURE

Due to the technology involved Galvanic Isolators are a bit difficult to test. New standards are being developed that will specify self testing isolators, but there are some technical difficulties that remain to be overcome and in the meantime they have to be tested by hand. There are a number of methods that can be employed, but the one that follows is the simplest and easiest:-

UNPLUG THE BOAT FROM SHORE POWER BEFORE STARTING THE TEST

1. Disconnect lead from one of the Terminals on the Galvanic Isolator so that you are testing it only.

2. Take a Digital Multimeter and set to the Diode test function

3. Put one lead from the Multimeter on one Terminal of the Galvanic Isolator and the other lead on the other Terminal

4. As the Capacitor in the Galvanic Isolator starts to conduct current, the reading on the Multimeter should rise to approximately 0.9Volts*

5. Remove the test leads from the Galvanic Isolator and short the two terminals of the Galvanic Isolator together to discharge the Capacitor

6. Repeat the test – this time with the test leads reversed. You should get the same result*

If you get the above results then the Galvanic Isolator is working OK and can be safely reconnected.

We recommend this test should be carried out once every six months.

*Charging of the Capacitor can take a little time depending on the Multimeter being used.

Interpreting the Readings

- If the reading is instantly 0.9Volts then the Capacitor is defective or there is no Capacitor

- If a Voltage of 0.45Volts is observed, one of the Diodes is shorted

- If there is a reading of 0Volts, then both Diodes could be shorted

- If there is a reading in excess of 0.9Volts, then one or both Diodes are open (not conducting) in which case you should stop the test before the Capacitor reaches 2.0Volts or you will damage it

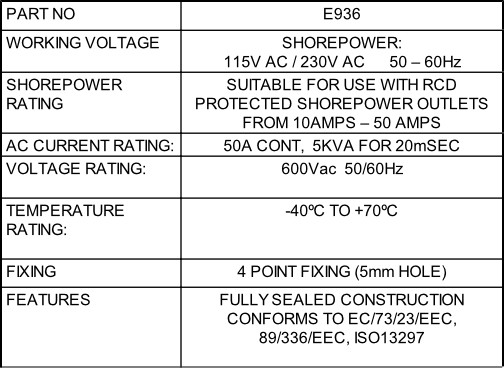

E936 GALVANIC ISOLATOR

Specification

Do I need a Galvanic Isolator?

Yes, if you use shorepower to provide a mains supply to your boat.

The latest CE and BMEA Regulations clearly state that AC Earths from Shorepower must be bonded to your Anode. As other Boats in the same vicinity as yours have the same bonding system, the Shorepower Earth Wire is potentially connecting the underwater metal parts from each Boat together. The water between the Vessels acts as an Electrolyte forming an Electrical Cell, which is similar to a low power battery. This will cause metals with a low galvanic number to transfer to metals with a higher galvanic number, which means that Electroplating will occur. This will damage and weaken the metal structure of your Boat.

What does a Galvanic Isolator do?

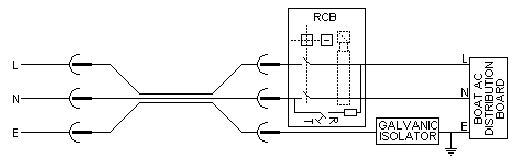

The Galvanic Isolator is fitted in the AC incoming Earth Lead interrupting any galvanic circuit and is bonded at the same point as the DC ground on the Boat.

It should be noted that earth bonding a legal requirement to ensure safety. It is not only illegal, but also dangerous not to bond AC Earths to metal parts and DC Negative on Board. A common earth point should be used.

| DC-DC Voltage Converters |

| DC-DC Battery Chargers |

| Battery Management |

| Marine |

| Safety |

| Lighting |

| Horsebox Electrics |

| Forklift Electrics |

| Gritter Voltage Dropper 24V to 12V |

| Step Up DC-DC Voltage Converters |

| 12V to 24V Voltage Converter |

| Step Down DC-DC Voltage Converters |

| 24V to 12V Voltage Converter |

| Trailer Voltage Converters |

| AVC19 Trailer Voltage Converter |

| E805 Trailer Voltage Converter |

| E1244 Trailer Voltage Converter 260W |

| Battery Monitors |

| 12V Battery Management System |

| 24V Battery Management System |

| Split Charge Control Units |

| Voltage Sensitive Switches |

| Battery Status Indicators |

| Voltage Regulators |

| 12V Split Charge Controller |

| 12V to 24V Split Charger |

| 24V Split Charge Controller |

| 24V to 12V Split Charger |

| E1154 10A 12V-24V Split Charger (13V Turn On) |

| E1155 20A 12V-24V Split Charger (13V Turn On) |

| E1042 12v 200A Split Charge Controller |

| E038 24v Split Charge Controller |

| E1158 12A 24V-24V Split Charger (26V Turn On) |

| E1159 24A 24V-24V Split Charger (26V Turn On) |

| E1152 24V-12V 15A Split Charger (26V Turn On) |

| E1153 24V-12V 30A Split Charger (26V Turn On) |

| E1198 24V-12V 45A Split Charger (26V Turn On) |

| E1040 1A Voltage Sensitive Switch |

| E1049 1A Voltage Sensitive Switch |

| E1056 1A Voltage Sensitive Switch |

| E943 12V Battery Status Indicator |

| E1107 12V and 24V Battery Status Indicator |

| E1096 12V 15A Voltage Regulator |

| E1297 12V 30A Voltage Regulator |

| E936 Galvanic Isolator |

| 12V Boat Battery to Battery Chargers |

| 24V Boat Battery to Battery Chargers |

| E1047 12v + 24v Digital Speed Switch |

| E1048 12v + 24v Digital Speed Switch |

| E1109 24V Dim Dip (Danor 24VHDP/5, 24VHDP/3, 113813-2) |

| E1121 Electronic Flasher (Danor 408834-3) |

| E1122 Electronic Flasher (Danor 408838-9) |

| E1260 Electronic Flasher (Danor C100, ERF 111004-8) |

| 24V to 12V Horsebox Battery Chargers |

| 12V to 12V Horsebox Battery Chargers |

| 24V to 24V Horsebox Battery Chargers |

| 24V to 12V Horsebox Voltage Converters |

| 24V to 12V Forklift Voltage Converters |

| 36V to 12v Forklift Voltage Converters |

| 48V to 12V Forklift Voltage Converters |

| 72V to 12V Forklift Voltage Converters |

| E921 48V Forklift Power Flasher |

| New Products |

| E772 used in Drag Racing Car |

| E1116 PTO Warning Light Control Box |